The post Flexible Small-Scale Generation Empowered by Once-Through Boiler Technology appeared first on POWER Magazine.

Distributed generation integrated with intermittent renewable generation responds to the growing need for highly flexible small-scale (less than 100 MW) power generation resources. The limiting factor facing plant designers is that the conventional heat recovery steam generator (HRSG) does not enable fast-acting power generation demanded by modern grid systems. John Cockerill Energy’s vertical once-through boilers fill this technology gap—combustion turbines are no longer constrained by the slow thermal performance of a HRSG when quick starts/stops, load following, or transient response to grid disruptions are routine. Also, the modular nature of the once-through boiler reduces installed cost compared to conventional field-erected HRSGs.

Cogeneration, combined cycle, and combined heat and power technologies are commonly used in flexible small-scale power installations of less than 100 MW. Developers of these facilities share the common design goal of maximizing plant operating reliability and efficiency while minimizing the lifecycle cost of plant ownership. John Cockerill Energy (JCE), ex CMI, a global leader in the supply of HRSGs, has introduced a new modular once-through boiler (OTB) that will change how small-scale power generation projects are designed in the future.

The heart of every distributed generation system is its HRSG. However, the HRSG is also the limiting factor in the thermal performance of a plant, particularly during startup/shutdown and when responding to grid transients. For some manufacturers, the solution has been to adapt tube and boiler drum metal thickness to reduce thermal stress. However, adding steel also adds thermal capacitance, which slows the thermal response of the HRSG, further complicates field erection, and adds material cost. JCE, on the other hand, uses a once-through boiler (OTB) design to avoid these design and operational pitfalls.

Inside the Once-Through Boiler

The most desirable HRSG design is one that meets three specific design requirements. First, the design must leverage the efficiencies of modular fabrication to reduce HRSG first cost and field erection time. Second, the design must reduce HRSG design complexity to increase plant reliability and reduce maintenance costs. Finally, the modern HRSG design must be capable of routinely performing rapid startups, shutdowns, and transient operations. In the following sections, we will assess the JCE vertical OTB against these design considerations and then consider a case study of a recent vertical OTB installation.

Modular Fabrication Reduces Installation Cost. Combined cycle plants have used traditional horizontal or vertical HRSG designs for decades. These HRSGs are characterized by multiple field-erected economizer, evaporator, and superheater modules with significant external piping, instrumentation, and controls. Further complicating erection is the number of sections added in multiple-pressure HRSGs. Each thick-walled steam drum limits the rate of change of pressure during startup and transient operations, and thus limits the plant’s ramp rate. Temperature limits within each HRSG module also limit flexible plant operations, so to avoid thermal damage to the heat transfer surface, routine cycling must be avoided or the plant will experience reduced HRSG life (Figure 1).

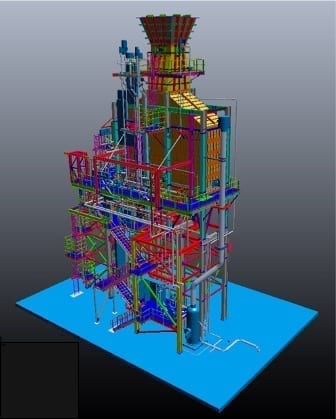

Further, the OTB is fabricated as a single pressure part, so field erection time and costs are minimized. For those projects, a single OTB module is shop manufactured and shipped with the serpentine tubing and tube sheets installed and fully pressure tested before shipping. Tube sheets, functioning as tube supports, are integrated into the modular box at constant tube pitch. Tube sheets are supported by cantilever supports bolted on the main columns (Figure 2).

The assembly sequence of an OTB with multiple modules is significantly simplified with this design. Individual modules, such as those shown in Figure 2, may be combined to produce the required amount of steam. The length of a particular module is limited only by shipping constraints. Dual-pressure OTBs are also available, with the separate serpentine tube systems arranged within a single module. Finally, note that the amount of field-erected structural steel is reduced because the need to hang multiple heavy boiler drums and associated external boiler piping is reduced. A single pressure part module OTB requires only three to five weeks for erection, including platforms, stairs, and seal welds, a substantial field erection cost savings for the owner.

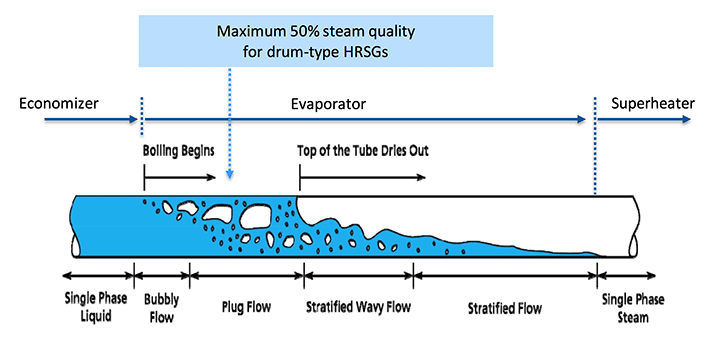

Once-Through Boiler Design. A distinctive feature of JCE’s OTB design is that water is heated, evaporated, and superheated in a single serpentine tube bank (Figure 3). This design approach eliminates the need for separate economizer, evaporator, and superheater modules with the associated interconnecting piping and instrumentation.

The OTB is designed for dry startup and operation. This approach to plant design provides an economical as well as an operational advantage. In the case of a conventional HRSG, each combustion turbine (CT) typically found in a combined cycle plant must idle or remain at a part-load condition to preheat the HRSG according to the manufacturer’s requirements, which lengthens the startup evolution.

The OTB operates as a single continuous process of steam production, and thus features an improved heat recovery efficiency. The OTB does not require the CT to pause during startup, nor does it limit the ramp rate of the CT due to steam temperature or pressure restrictions. Also, the OTB may be shut down and restarted at any time, without reducing the CT load. If the plant is configured with a steam turbine, then initial steam production from the OTB is desuperheated and bypassed to the condenser until suitable steam temperatures and pressures are reached. Steam may be introduced into the turbine thereafter.

The OTB is designed to operate with variable steam flow, as low as approximately 30% CT load, while maintaining superheat temperature, unlike conventional HRSG designs. The modular design of a serpentine tube core supported by a tube sheet reduces the thermal mass of the OTB so that it can quickly respond to a CT load change. The thermal mass reduction is principally due to the elimination of the thick-walled boiler drum(s) that add thermal capacitance to the steam production circuit.

The net effect is complete de-coupling of the CT from the steam cycle, allowing the CT to maintain its quick-start capability in response to load changes or transient grid conditions. This highly desirable feature is not found in conventional HRSG designs but is essential for modern, flexible power plants that connect to a grid with intermittent renewable generation.

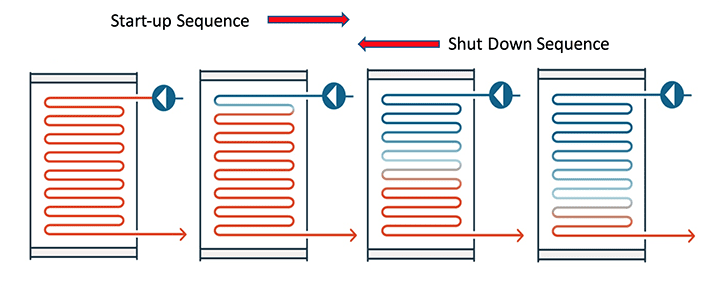

Transient Operation of the OTB. Modern plants must operate flexibly to ride through unforeseen grid transients and must startup/shutdown quickly when required by the grid operator. The OTB starts faster because the CT follows its standard startup protocol, and the OTB can operate dry.

Regular operation of an OTB begins with a standard startup and synchronizing of the CT to the grid. The OTB hot-start sequence begins with the CT at full load and the coil bank at gas temperature. The OTB control system begins by slowly adding feedwater and then increasing flow according to a defined ramp rate until the feedwater cools the inlet rows of the OTB. As the OTB warms, steam superheat conditions are set by the feedwater flow rate. Startup and load transient response are no longer limited by drum metal temperatures as the vertical OTB may be started and run dry.

The OTB control setpoint switches to temperature control based on tube metal temperatures and various control algorithms once design superheat conditions are achieved. The design temperature profile is reached at this time, and the stack temperature normalizes. Also, the location of the “dry-out zone” will stabilize (Figure 4).

Suitable tube material selections are essential to run the OTB dry. Tubes in ferritic material SA178A or SA213 T11/T22 are the standard material selections. Tube materials used in conventional drum-type boilers may be specified if the OTB is going to be run only “wet.” Naturally, tube and fin material selections are based on the CT exhaust temperature, steam temperature and pressure, and evaporator inlet temperature.

The region between the tube sheet holes experiences the most significant thermal stress in the OTB. Finite element analysis was used to properly design these high-stress regions of the OTB dry-operating mode. The tube sheets are fixed in place by tube sheet supports integrated into the modular box. The tubes are installed with constant tube pitch in both vertical and horizontal directions of these tube sheets.

Proper boiler water chemistry must also be maintained for extended tube life to minimize boiler tube pitting, corrosion, scaling, and carryover. Conventional drum boilers require water treatment chemicals, such as phosphate, and periodic blowdown for removal of suspended solids and bottom sludge, to avoid internal tube damage. The OTB takes a different approach by eliminating the chemical treatment and blowdown systems used to maintain condensate quality found in conventional HRSG plants. Instead, the OTB plant uses a condensate polisher typically installed between the condenser and HRSG inlet. This approach reduces overall system maintenance and chemical costs, while extending boiler tube life.

Case Study: Bridge Power, Ghana, West Africa

The Bridge Power Project is expected to supply efficient, reliable, low-cost power for Ghana’s growing economy. The facility is currently being constructed in two phases. Stage 1A includes five fast deployment General Electric (GE) TM2500+ gas turbines running in simple cycle mode (the TM designator stands for the truck-mounted version of the familiar LM2500+). An added 52 MW of combined cycle capacity will be added in Stage 1B with the installation of a single steam turbine and five JCE OTBs (Figure 5).

The Bridge Power facility requires maximum operational flexibility with an extremely compressed construction schedule planned to convert the already operational simple cycle CTs to combined cycle operation. The OTB was the ideal choice for the project based on its capability to run dry, which decouples the CTs from the steam cycle. The modular pressure part box OTB design maximizes shop fabrication by pre-assembling 100% of the pressure parts into a single module.

In January 2019, GE—the prime contractor—awarded John Cockerill Energy the contract for five dual-pressure OTBs. The JCE scope of work includes the design, engineering, manufacture, and supply of the boilers. The pressure parts were manufactured in Korea. GE subcontracted boiler erection to Metka. The plant is fueled by liquefied petroleum gas (LPG) with distillate oil as a backup fuel. The OTB steam conditions are 512C/64.8 barA for the high-pressure and 232C/4.6 barA for the low-pressure loop. The plant expects to run at baseload with periodic cycling operations. The schedule calls for substantial completion of the project in December 2020.

—Ravi Krishnan is founder and managing director of Krishnan & Associates Inc., a specialized energy industry marketing consulting firm.

The post Flexible Small-Scale Generation Empowered by Once-Through Boiler Technology appeared first on POWER Magazine.