What is a microreactor and why would you want one? The definition could be debated, but nuclear reactors in the 1 MW to 20 MW range generally fit the bill, and there are countless possible applications for the technology.

“This could be used for disaster relief. This could be used for mines, remote communities—on a 24/7 basis. It can be used for data centers, industrial plants—anyone that wants to be off the grid, even though maybe they’re on the grid now, but they want to be off the grid—so, military bases. The opportunities here are just endless,” David Durham, president of Energy Systems with Westinghouse Electric Co., said as a guest on The POWER Podcast.

Westinghouse is developing a microreactor called eVinci. It’s a next-generation, small nuclear energy generator intended for decentralized generation markets. The eVinci design is very different from commercial light water reactor plants currently in service around the world. “The differences are substantial. There’s no water. There’s no moving parts. Literally, there’s hot air that transfers through the tubes into the power conversion container, and then, that generates electricity,” Durham explained. “So, it’s simply a hot air transfer system.”

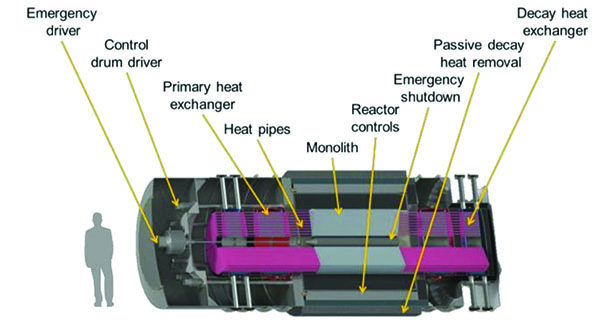

The eVinci’s unique core design is built around a solid steel monolith with channels for both heat pipes and fuel pellets. Each fuel pin in the core is adjacent to three heat pipes for efficiency and redundancy. The large number of in-core heat pipes is intended to increase system reliability and safety. Decay heat can also be removed by the heat pipes with the decay heat exchanger.

Although the use of heat pipes in nuclear reactors is somewhat new and perhaps not as familiar to the nuclear industry, liquid metal heat pipe technology is mature and robust with a large experimental test database to support implementation of the technology into commercial nuclear applications. In fact, the Los Alamos National Laboratory worked to develop and prove heat pipe technology for space application.

“What’s interesting about this technology is it’s totally self-contained in three containers, and these containers fit on the back of an 18-wheel truck,” said Durham. “So, this isn’t your image of building a big power station with constructors and cranes and everything else. It’s basically three CONEX boxes that are then taken to a site, which requires very little work—a concrete basemat, that’s it—and then they’re plug and play together, so that within just about three months, you’ve got electricity at that site.”

Westinghouse claims the reactor core “can easily run for more than 10 years without the need for refueling.” Furthermore, units can be controlled and monitored remotely with literally no personnel onsite. It remains unclear, however, if regulators will allow that type of operation.

“If there are staff onsite, it’ll be a very minimal number. There’s really very little maintenance to be done. This thing is sealed and operates for five years autonomously,” said Durham. “Quite frankly, if there are operators onsite, they’re basically just going to be monitoring—there’s nothing really for them to do.”

Durham suggested the eVinci design could eliminate the need for diesel-fueled power generation in remote locations. He noted that diesel is “one of the dirtiest fossil fuels out there,” and an “extremely expensive way to generate electricity, particularly when you need to ship it into remote areas.”

Westinghouse conducted a feasibility study in partnership with Bruce Power, a Canadian private-sector nuclear generator that produces about 30% of Ontario’s power annually. The study found that a single eVinci microreactor could be “between 14% and 44% more economic than a diesel generator, depending upon the price of diesel fuel and the price for carbon,” according to a Westinghouse-issued statement. “The feasibility study determined that there are at least 100 communities in Canada—up in the north—where this could be a game-changing technology to eliminate almost 100 million liters of diesel fuel being burned per year,” Durham said. Additionally, in mining scenarios, Westinghouse said that the eVinci microreactor unit with diesel backup “could reduce carbon emissions by about 90% in Canada.”

So, when can we expect to see the first eVinci unit enter commercial operation? “We’re still in the process of scaling it up,” Durham explained. “And then, of course, we have to go through the licensing process.”

Westinghouse announced on Dec. 14 that it had filed a pre-application Regulatory Engagement Plan for the eVinci microreactor, detailing the planned pre-licensing application interactions with the U.S. Nuclear Regulatory Commission (NRC). This regulatory milestone also sanctions substantial technology validation progress achieved on the overall development plan of eVinci microreactors, the company said. The plan includes information on the design as well as the regulatory strategies envisioned, including manufacturing, transportation, operation, and refueling phases of deployment. Meanwhile, Westinghouse plans to initiate the Canadian licensing process in the coming year, Durham said.

“We definitely see this being commercialized by the end of this decade,” said Durham, who sees a bright future for nuclear power. “I think that we’ll definitely see a significant growth in nuclear power at large. I think it’ll include eVinci, certainly, in a big way.”

To hear the full interview, which includes additional discussion about Westinghouse’s AP1000 pressurized water reactor, small modular reactors, the feasibility study process, details about countries that have shown interest in Westinghouse’s nuclear technology, and how government policies could affect growth, listen to The POWER Podcast. Click on the SoundCloud player below to listen in your browser now or use the following links to reach the show page on your favorite podcast platform:

For more power podcasts, visit The POWER Podcast archives.

—Aaron Larson is POWER’s executive editor (@AaronL_Power, @POWERmagazine).

The post How Microreactors Could Change the Nuclear Power Industry (and the World) appeared first on POWER Magazine.