Ultra Safe Nuclear Corp. has opened a pilot fuel manufacturing facility that will produce TRi-structural ISOtropic (TRISO) coated fuel particles and the company’s proprietary fuel for use in its high-temperature gas reactor (HTGR).

The Pilot Fuel Manufacturing (PFM) facility, located at the East Tennessee Technology Park (ETTP) in Oak Ridge, Tennessee, is one of the first U.S. private sector manufacturing facilities dedicated to developing advanced reactor fuel. It is now ready to process feedstock uranium powder into TRISO fuel particles and subsequently produce Ultra Safe Nuclear’s patented fully ceramic microencapsulated (FCM) fuel in multiple kilogram quantities, the company said on Aug. 18 as it declared the facility officially open.

The company plans to produce, test, and qualify the fuel at the facility for use in its Micro Modular Reactor (MMR) Energy System, which is a fourth-generation 5-MWe (15-MWth) HTGR, and other advanced terrestrial and space energy systems that it is also developing. Pivotally, the PFM will allow the company to test equipment and processes that could be scaled into larger fuel manufacturing facilities.

The PFM features the “same production-scale modules” for manufacturing TRISO-coated fuel particles and the company’s FCM fuel that will go into Ultra Safe Nuclear’s future commercial fuel manufacturing facility, the company said. “In the process, PFM will also codify and demonstrate the manufacturing modules that will be used in the company’s future commercial fuel manufacturing factory,” it said.

A Big Step for Commercial TRISO Fuel Development

The facility’s opening, which was attended by several high-profile state and Department of Energy (DOE) officials, marks a notable boost for private sector TRISO fuel development.

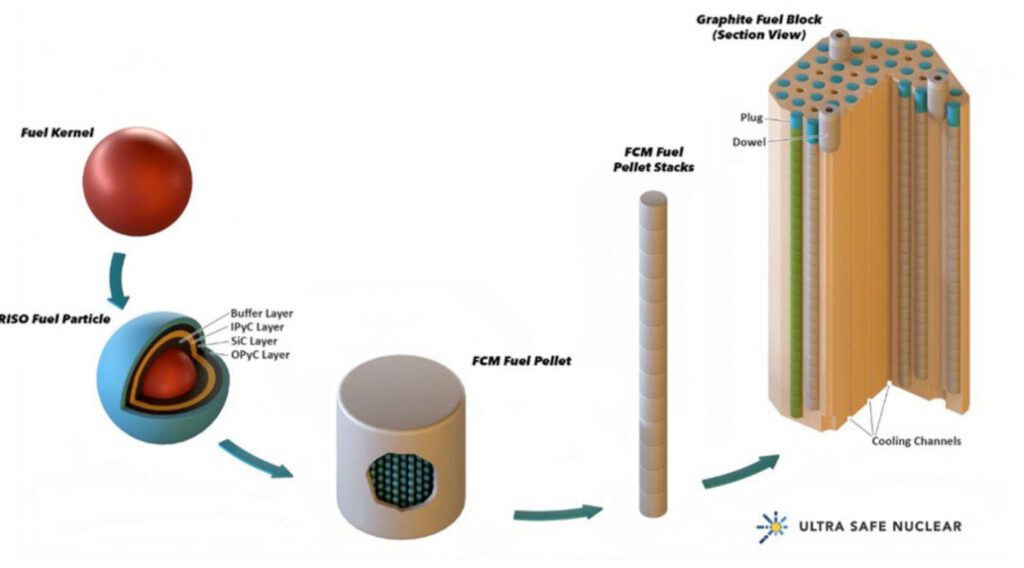

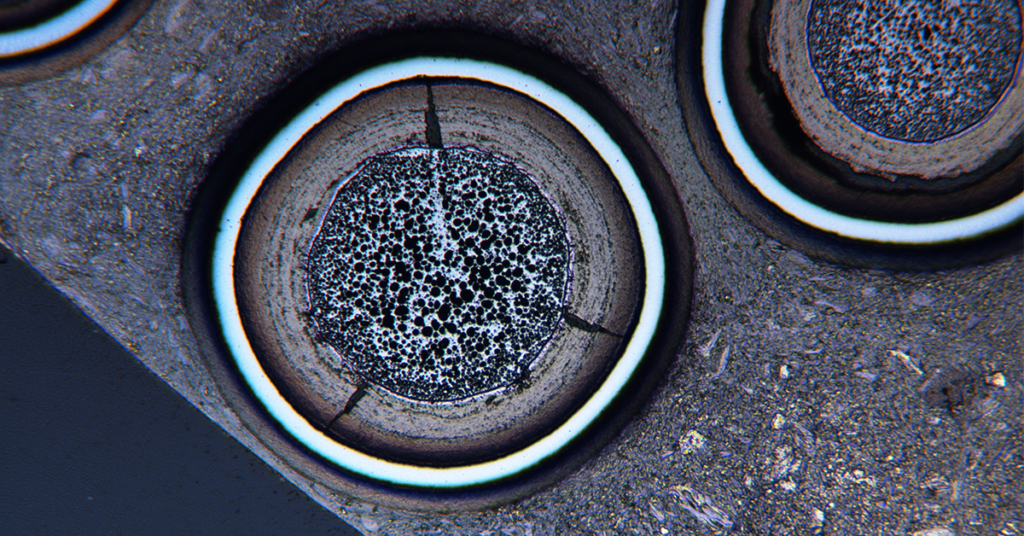

TRISO, a robust, microencapsulated fuel form developed originally for use in HTGRs in the 1950s, comprises “particles”—some about the size of a poppy seed—which typically consist of a spherical fissile “kernel” sheathed by several layers of pyrocarbon (PyC) and a silicon carbide (SiC) layer. TRISO’s most lauded benefit is that each particle acts “as its own containment system thanks to its triple-coated layers,” the DOE has explained. “This allows them to retain fission products under all reactor conditions.” (Read more about TRISO nuclear fuel in POWER’s March 2021 feature: “The Allure of TRISO Nuclear Fuel Explained”)

Industry observers suggest that because TRISO enables a high-temperature output in advanced reactor designs, it could potentially boost the use of nuclear energy beyond electricity generation into energy sectors, for example, that are currently dominated by fossil fuels such as process heat, oil shale and sand reprocessing, petroleum refining, desalination, and hydrogen production. Meanwhile, owing to TRISO’s fuel form flexibility, and despite its origin and historic use in HTGRs, the conventional particle design could be well-suited to several types of advanced, high-temperature reactors (HTRs), including the fluoride salt–cooled HTRs, and microreactors.

However, commercial TRISO development in the U.S. is limited, owing in part to crucial technology and supply chain gaps that exist for high-assay low-enriched uranium (HALEU) fuel systems, materials, and fabrication technologies. Only a handful of companies are currently spearheading efforts to establish TRISO production lines.

Industrial fuel vendor BWX Technologies (BWXT) has manufactured and certified TRISO-coated kernels and fuel compacts in production-scale quantities, and, so far, has the nation’s only TRISO production facilities that are currently licensed and operating. But its existing production line, along with ongoing capacity expansion, caters largely to Department of Defense microreactors, space reactors, and civil advanced reactors.

Meanwhile, X-energy, a winner of the DOE’s Advanced Reactor Demonstration Program (ARDP), is building “TF3,” a HALEU and TRISO-based fuel facility at the Horizon Center industrial park in Oak Ridge, Tennessee. X-energy submitted the nation’s first-ever HALEU fuel fabrication facility license application to the Nuclear Regulatory Commission (NRC) in April. The NRC’s application review is expected to take 24 to 36 months, and X-energy has said it expects to begin operating TF3 “in the 2025 timeframe,” after the NRC issues a special nuclear material (SNM) license. X-energy plans to initially produce 8 metric tons of fuel per year (MTU/year), supporting about 16 advanced reactors (including X-energy’s Xe-100 design) at the the facility.

Ultra Safe Nuclear’s FCM Fuel

Ultra Safe Nuclear has also so far made notable strides since it initiated development of the MMR and FCM fuel in 2011.

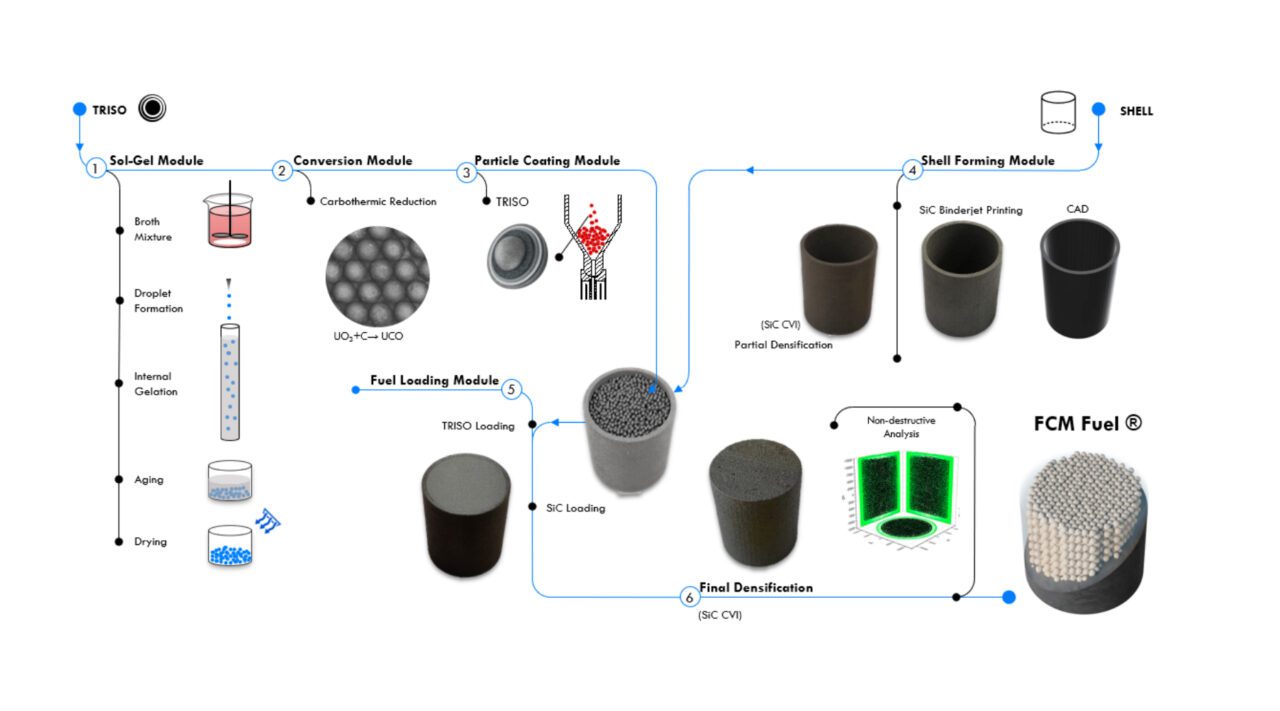

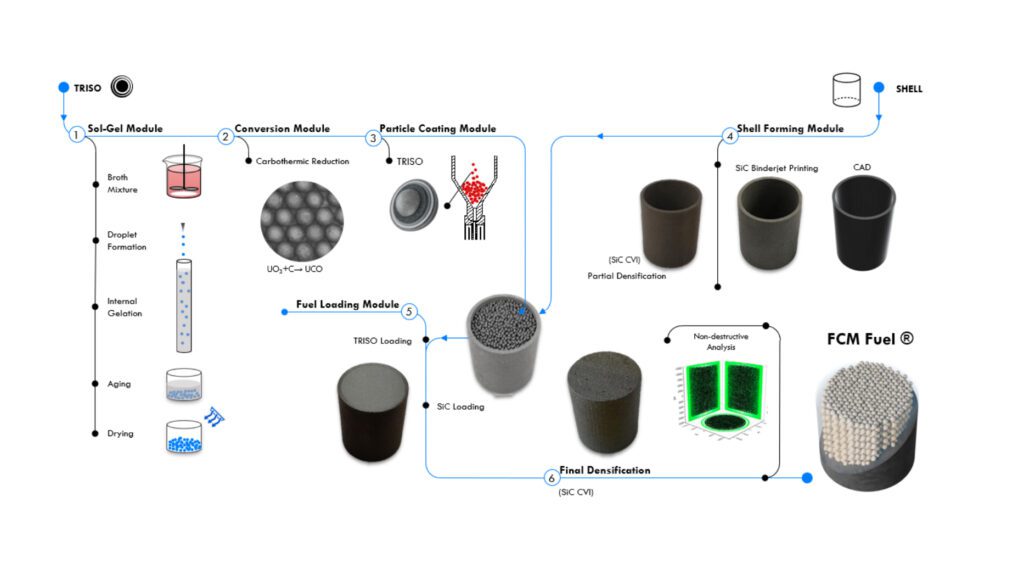

FCM fuel consists of coated nuclear fuel particles embedded inside a dense and fully sealed SiC matrix, Francesco Venneri, Ultra Safe Nuclear CEO, last year explained to POWER. “The specific coated fuel particles are TRISO microspheres that provide micro-encapsulation of the fuel with multiple pyrocarbon and a SiC coating layer. Using FCM technology, an additional layer of protection against radionuclide release is added by taking advantage of SiC as the matrix for these coated fuel particles. This micro-encapsulation further enhances radionuclide retention capability of the fuel and allows for design and deployment of ultra-safe nuclear energy systems,” he said.

According to Venneri, the fuel is also flexible. “FCM may host the well-established uranium oxide-carbide (UOC) TRISO particles or more recently developed variants such as the uranium nitride (UN) TRISO. The SiC matrix may be produced using conventional methodologies that allow for relatively simple geometries such as cylindrical compacts or via additive manufacturing methods that facilitate production of fuel elements with highly complex configurations,” he said.

“The advanced TRISO and manufacturing technologies have been systematically tested at Oak Ridge National Laboratory (ORNL) and through leveraging and licensing of these technologies, Ultra Safe Nuclear is able to develop tailored energy systems and facilitate their industrial deployment,” he noted (see the full interview here).

Pilot Facility Set Up in Less Than 12 Months

While Ultra Safe Nuclear last year established a Salt Lake City, Utah, facility to advance ceramics production technologies for the company’s MMR systems, the Seattle-based company has been pursuing the PFM facility to expand its fuel capabilities. The company last week told POWER that it purchased the PFM facility site located at ETTP, site of the Manhattan Project’s K-25 gaseous diffusion plant, as well as an industrial building from Heritage Center LLC in 2021. It was able to get the facility up and running in less than a year owing to the region’s specialized workforce and industrial ecosystems, it said.

“It’s great to get PFM up and running here in Oak Ridge, which has a uniquely qualified nuclear workforce and contractor community,” said Dr. Kurt Terrani, executive vice president of Ultra Safe Nuclear. “We selected this location specifically, and the support we’ve gotten to build out this first-of-its-kind facility with this level of quality and care, on an aggressive schedule and on budget, is just phenomenal.”

So far, Ultra Safe Nuclear has established a “complete array of production-scale modules required for TRISO and FCM production” at the PFM facility. The facility is also capable of utilizing a 3D-printing process licensed from ORNL for manufacturing refractory ceramic carbides. As significantly, the facility features “licenses for processing pilot-scale quantities of both natural and enriched uranium needed for fuel production,” the company said.

The company now anticipates a series of fresh milestones that could mark significant advancements and move the niche nuclear fuel closer toward commercialization by the end of the decade. When produced, FCM fuel will go through a “rigorous testing and qualification program to be certified for use in the U.S.,” the company said.

A first step, now slated to wrap up in 2023, will involve irradiation testing at the High Flux Reactor (HFR) in Petten, Netherlands. The company kicked off that stage with a Dutch group, Nuclear Research & Consultancy Group (NRG), in June 2021. The program’s goal is to demonstrate the safety of FCM fuel for the 20-year lifespan of the Ultra Safe Nuclear MMR. Testing is underway through a two-stage irradiation process.

Between 2025 and 2026, FCM fuel will then undergo post-irradiation examination to verify its performance. In 2026, Ultra Safe Nuclear expects to submit an FCM fuel qualification topical report to the NRC, essentially requesting approval for its use. However, the company expects testing will continue through 2030 to cover the fuel’s lifetime.

The fuel performance and testing schedule is especially notable given Ultra Safe Nuclear’s burgeoning prospects for the MMR. While privately funded, and American-owned and controlled, Ultra Safe Nuclear is part of a joint venture with Ontario Power Generation, known as Global First Power, that has proposed to build, own, and operate a full-scale 5-MWe/15-MWth MMR reactor at Canadian Nuclear Laboratories’ (CNL’s) sprawling 10,000-acre Chalk River site in Ontario. The Chalk River MMR is expected to be operational in 2027.

Separately, the University of Illinois at Urbana-Champaign (UIUC) in June 2021 formally kicked off a project to partly re-power its 85-MW Abbott cogeneration plant with an MMR Energy System. The university submitted a letter of intent to the NRC to apply for a license to construct a research and test reactor on the UIUC campus.

In February 2022, meanwhile, Copper Valley Electric Association (CVEA), an “islanded utility” located in Glennallen, Alaska, said it was exploring the feasibility of a 10-MWe micro facility featuring the MMR Energy System. If built, the project could become Ultra Safe Nuclear’s first commercial project.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).

The post Pilot Advanced Nuclear Fuel Manufacturing Facility Opens appeared first on POWER Magazine.