About six years ago, I was excited and eager to have regular opportunities to get out from behind my computer-aided design (CAD) workstation and visit our utility’s substations, transmission line right of ways (ROWs), and telecom sites throughout our service area in Texas. Most of us engineers and technicians looked forward to these inspections as a chance to escape the confines of our cubicles.

However, for many, the thought of putting on the hot, heavy, and uncomfortable lab coats we were using at the time was extremely unpopular, especially in the Texas heat. It didn’t take long for me to see their point. One engineer who was close to retirement told me, “I don’t even go out in the field anymore, because I’m afraid of having a heat stroke. At my age, it’s a health hazard.” Even though field verification is a necessary part of design-build companies’ best practices, many employees may still be reluctant to wear flame-resistant (FR) clothing to complete the task.

On the other hand, when you’re shivering in the snow, the dangers of heat and flame probably aren’t the first things that come to mind. But even in cold weather, thermal hazards such as arc flash and flash fire pose a serious concern. In fact, when winter brings dry air and strong winds, it can literally help fan the flames.

Understanding the ins and outs of FR clothing can go a long way toward protecting utility workers from burn injuries and fatalities. There’s a lot to learn when it comes to implementing an effective FR clothing program.

One of the most obvious ways to combat the cold is to bundle up in extra layers of clothing. But in environments where thermal hazards are present, it is important to ensure each of those layers is flame resistant. A non-FR jacket worn over FR clothing can ignite and burn, injuring the wearer. On the other hand, an FR jacket worn over an FR shirt offers an extra layer of protection.

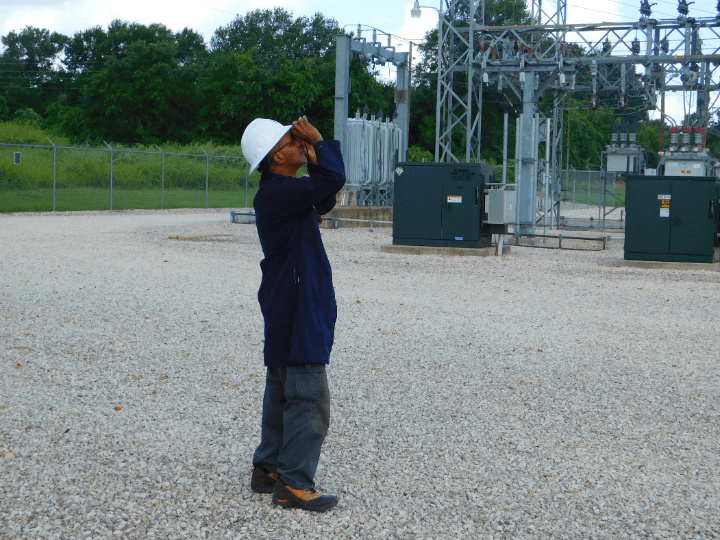

It makes sense that comfort and style weren’t always top priorities in FR clothing, after all, the main focus was protection. But we now know that comfort and style can impact the safety benefits FR workwear provides. The more comfortable FR clothing is, and the more that FR styles align with modern preferences, the more likely it is that workers will wear the proper apparel and have the protection they need when they need it (Figure 1).

Unpredictable Weather: Preparing for Cold and Hot

Based on personal experience, I can elaborate on all of the above. Here are some typical scenarios that I learned from field inspections during my 12 years working for two major utility providers in Austin, Texas.

A few years ago, while on a field inspection tour of several 345-kV substations in West Texas, our Telecom and Substation design team spent three days and nights on an as-built and pre-final construction visit to various locations in our company’s service area. It was early February, and owing to drastic temperature fluctuations known to exist in that part of the southwest, I packed accordingly.

Our personal protective equipment (PPE) safety guidelines are clear when it comes to appropriate FR clothing requirements while in high-voltage environments. However, our team, at that time, included two new, young interns on their first field trip.

We left Austin early that morning with the temperature in the 70s. Some of our team packed according to Central Texas early springtime conditions. By the time we reached Fort Stockton after sundown, the temperature was in the 50s. The next morning, it had dropped below 12F, and as we watched the news in the hotel restaurant, the forecast called for freezing drizzle with icy road conditions and travel advisories for the entire area.

I was prepared and dressed in layers, being a U.S. Air Force veteran accustomed to arctic cold weather conditions. However, even I was worried about our team venturing out that day. We decided to call the field construction coordinators (FCCs) and our supervisor for advice. The FCCs were already en route to the site in the pre-dawn weather, and were completely unafraid of road hazards due to their experience and heavy-duty off-road vehicles.

After some deliberations and waiting for the rain to subside, we headed out, and the harsh realities of not being prepared for this type of weather was a sobering thought for all of us. By the time we reached the substation 45 minutes later, the rain had stopped, it was foggy, the construction crews were huddled in their vehicles, and the last temperature reading I noticed before my phone froze was somewhere in the 20s. This is when we all had to put on our warmest clothing, and as required, the FR lab coat had to be worn on the outside. We decided to seek shelter in the control house onsite to conduct our tail-board briefing.

As stated above, one of the most obvious ways to combat the cold is to bundle up in extra layers of clothing, but in environments where thermal hazards are present, it is important to ensure each of those layers is flame resistant. A non-FR jacket worn over FR clothing can ignite and burn, injuring the wearer. On the other hand, an FR jacket worn over an FR shirt offers an extra layer of protection.

Well, in our case, each of those layers of clothing was not flame resistant. This is something we were not cognizant of at that moment, because all we cared about was protection from the numbing cold. I loaned out one of my caps and pairs of gloves to the interns as we took turns inspecting the area and taking photos. Our hands were too numb to hold a camera or take notes for more than a few minutes. However, we still had to complete our tasks of measurements and verification of new and existing structures. We decided to retreat back to the warmth of the control house for relief and to gather our notes.

Departing there, we traveled to the next site, and within about an hour the weather cleared up, temperatures rose to the mid-70s and higher, and gradually, we found ourselves in sweltering heat by mid-afternoon. None of us had light-weight FR shirts or pants at the time, as they were not available to all employees, or simply because of a lack of preparation on our part.

Hot Weather

Here’s another scenario. It’s the middle of July in Central Texas, and our design team was scheduled for an as-built inspection of several substations within a 200-mile radius of our utility’s service area. Plans had been issued for construction (IFC) or issued for revision (IFR) for each project, and with the rolled-up plan sets in hand, the team set out around sunrise. The maintenance and construction crews had left earlier, because they knew better. Since the design team is only required to do periodic inspections during certain phases of the project, these trips can be scheduled months apart.

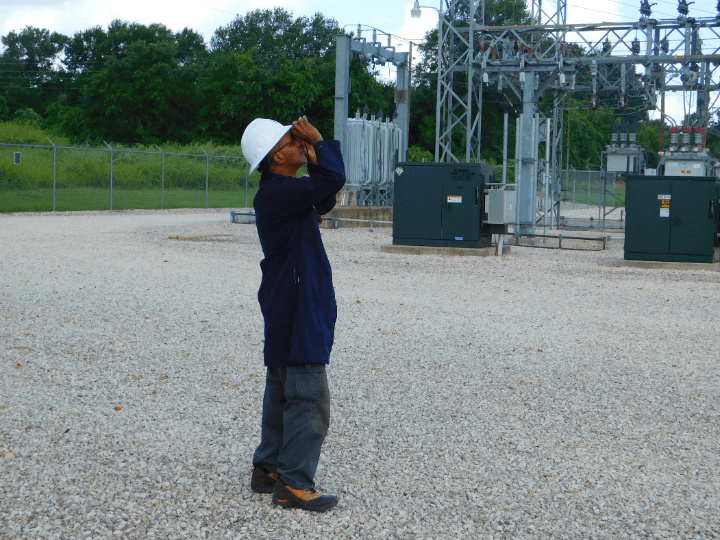

Our gear included all the required PPE—hard hat, safety shoes, safety sunglasses, gloves, measuring devices, insect repellant, gate keys, water, and two of my favorites, high-powered field binoculars (Figure 2) and a compass. But, the most important PPE item needed is FR clothing, in this case, a heavy, woolen, navy blue lab coat. From 1996 until the summer of 2019, this was the official FR garment worn by all non-construction and maintenance personnel allowed onsite in a substation at the company I worked for.

It is hot, stuffy, and cumbersome. The material is a tightly woven fabric made of 88% cotton and 12% nylon. It has an arc thermal performance value (APTV) rating of 12.4 calories per square centimeter (cal/cm2) and meets National Fire Protection Association (NFPA) 2112 standards. For us, it was just a necessary evil. One summer, we had some consultants from the Midwest visit our substation facilities, and they were required to follow protocol by wearing those FR lab coats. Needless to say, they found our FR clothing requirements to be overwhelming.

Shortly after this, our company purchased a new line of lightweight, comfortable, and stylish FR clothing that was available to all. This eventually became an open topic of discussion at safety meetings. Sometimes, continuous process improvement can take a long time to gain acceptance in an organization, but in the end, employees feel safer and more confident working under extremely hazardous conditions in extreme weather.

Lessons Learned

Here are some things to remember when preparing to work in areas that require FR clothing:

- Be aware of conditions that could change when traveling outside of temperate zones in your state. Consider all seasonal weather possibilities.

- Review challenges encountered in the field regarding uncomfortable FR clothing issues as soon as possible, and encourage honest dialog between staff and management without fear of reprisal.

- Take extra time to ensure all team members (especially technical staff who are not accustomed to working in extreme outdoor weather conditions) are properly supplied with light, layered PPE.

- If FR products are uncomfortable or unsightly, workers may be tempted to make alterations to them, or worse, skip wearing them altogether. Consider options that people will feel comfortable wearing.

- In the past, FR clothing had a reputation for being heavy and stiff, but that is no longer the case. Consider upgrading to the latest materials to ensure workers are unhindered while performing their jobs.

Finally, FR fabric breathability, weight, moisture management, and overall clothing comfort has improved through the development of multi-hazard protection. Products that combine FR properties with other safety benefits, such as chemical-splash protection (CP), offer a single protective garment for workplaces where previously two or more separate garments would often have been needed to address each hazard.

Consult the standards

The most important consideration in any PPE decision is safety. To ensure the products you select offer the appropriate level and type of FR protection, it is helpful to review the safety standards that apply to your industry. For example, NFPA 2112 provides protective apparel requirements for work environments where flash-fire hazards are present, and NFPA 70E addresses PPE requirements for workplaces with arc-flash hazards. In addition, NFPA 652 outlines apparel requirements for environments where combustible dust is present.

—Stan Bell is a freelance author and the owner of Graftek Designs. He is a retired telecom structural designer, formerly with Austin Energy and Lower Colorado River Authority.

The post The Case for Lightweight Flame-Resistant Clothing appeared first on POWER Magazine.