In July 2016, a coal silo collapsed at an Indiana power plant. The root cause was identified as cracking of the cone-to-skirt weld. Warnings to inspect this vulnerable weld were published widely in conference proceedings and trade journal articles. Nevertheless, coal silos continue to fail at an alarming rate (Figure 1), which suggests that the needed inspections weren’t completed by all power producers.

|

| 1. Recent failures of cone-to-skirt welds on large coal silos point to the need for ongoing inspections. Courtesy: Joe W. Frey Engineering Associates, LLC |

If you have any of these suspended cone silos (Figure 2) in your plant and are not yet doing non-destructive evaluation (NDE) inspections of their cone-to-skirt welds, then you need to start today.

|

| 2. Coal silos like this need our immediate attention! Courtesy: Joe W. Frey Engineering Associates, LLC |

Granted, this particular design is a real challenge to inspect, because the silo’s liner seals over the galvanic cell (in layman’s terms, a corrosion sandwich) that is created at the union of the stainless-steel liner and the carbon-steel structure. The NDE technologies that can inspect this “corrosion sandwich” include:

- Visual inspection. This means a trained inspector not only eyeballs the weld, but also reviews the system’s documentation, studying the as-built drawings versus the design drawings, and the system’s operations and maintenance history.

- Radiography. If your system’s geometry is conducive to this test.

- Ultrasonic testing (UT) with full-matrix capture. This can detect the initiation of tiny cracks before they grow large enough to cause catastrophic failure. If you think you know all about ultrasonic testing, think again, because for many years ultrasonic testing was limited to thickness measurement. However, many other methods of ultrasonic inspection have recently gained acceptance. The older, thickness-measurement method used one transducer that introduced ultrasonic energy perpendicular to the inspection surface. More recent UT methods introduce various modes of sonic energy at various angles to the surface, enabling the inspector to detect and measure more precisely the depth of cracks in the material, and to detect flaws in welded joints. The more-advanced UT methods also incorporate scanning devices that record the location of each transducer and display the resulting data in a user-friendly, three-dimensional image. Perhaps the newest UT method to gain widespread acceptance is “phased-array,” so named because it uses a large array of multiple-probe segments. Each segment intermittently sends and receives ultrasonic pulses, sequenced and displayed by a computerized controller to reveal any cracking.

All of these “in-section” methods will be assisted greatly by the use of a full-scale mockup of the system.

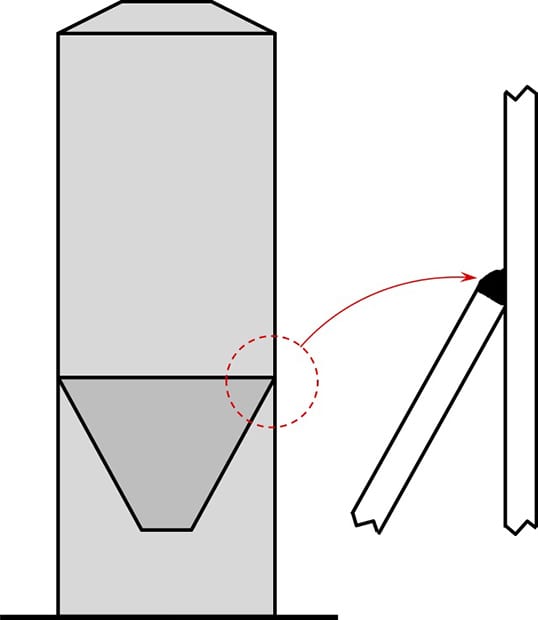

In conclusion, this article is a call to action. A call to our American Society of Mechanical Engineers (ASME) code committees, our insurance carriers, and all power producers for increased NDE inspections of the cone-to-skirt welds (Figure 3). Whether through visual inspection, radiography, ultrasonic testing, or a combination of all three, coal silo failures hopefully will become a thing of the past.

|

| 3. Advance ultrasonic testing can inspect the vulnerable weld. Courtesy: Joe W. Frey Engineering Associates, LLC |

—Joe Frey, PE is a long-time member of several ASME code committees and a failure analyst with Joe W. Frey Engineering Associates, LLC; and Rob Swanekamp, PE is founder and director of the HRSG User’s Group Inc.

The next HRSG User’s Group Conference will be co-located with the ELECTRIC POWER Conference & Exhibition April 23–26, 2019, at the Mirage Events Center, Las Vegas, Nevada.

The post Coal Silo Failures Reveal the Need for NDE Inspection appeared first on POWER Magazine.