World-First Test Production of Fossil-Free Hydrogen-Reduced Sponge Iron Completed

The post World-First Test Production of Fossil-Free Hydrogen-Reduced Sponge Iron Completed appeared first on POWER Magazine.

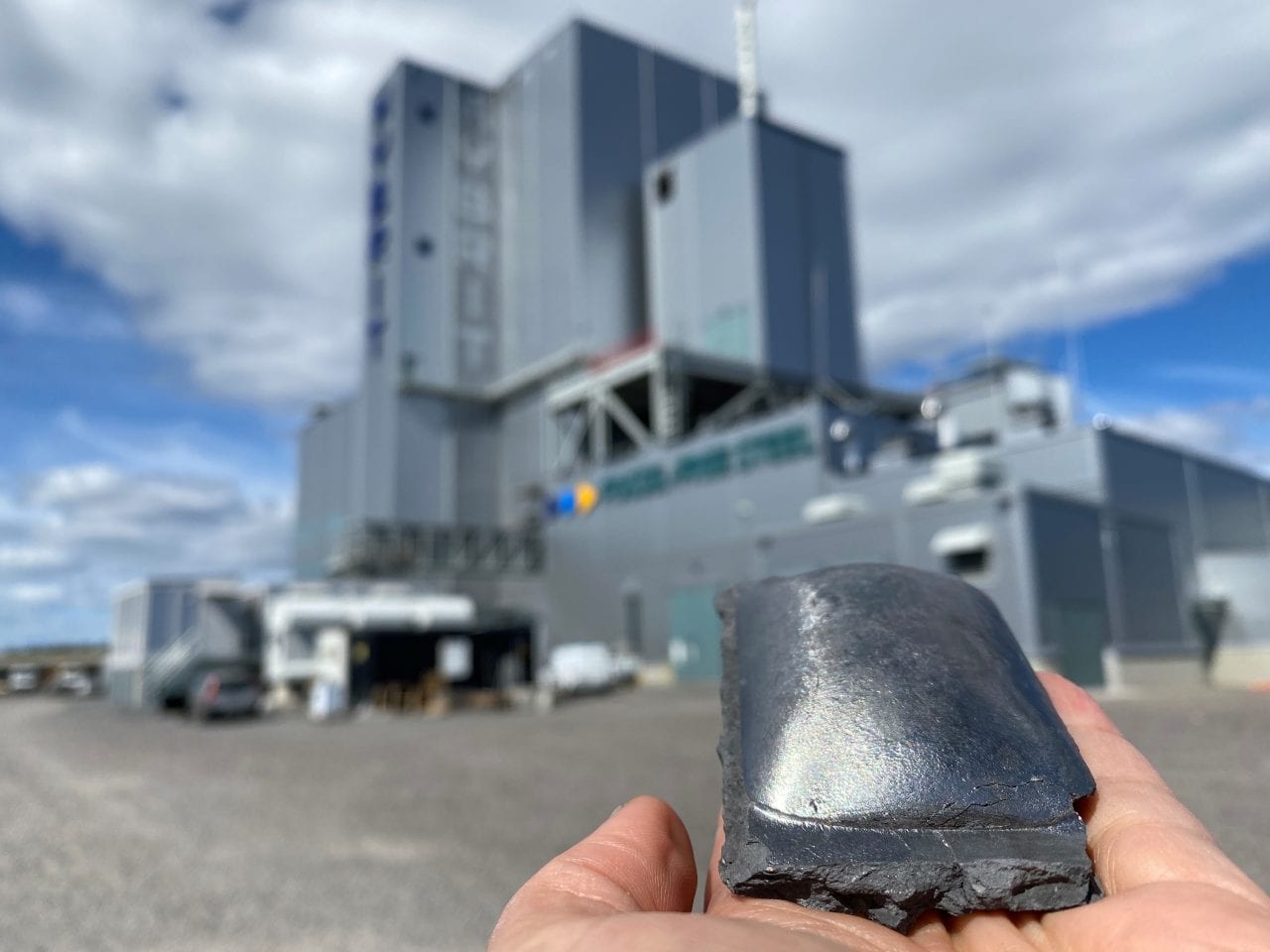

A pioneering pilot project in Lulea, Sweden, designed to produce “fossil-free” steel has successfully completed test production of sponge iron, demonstrating it is possible to use hydrogen made with fossil-free power to reduce iron ore, instead of coal and coke.

Swedish energy company Vattenfall, mining company LKAB, and steel manufacturer SSAB—companies that are collaborating under the joint initiative, dubbed “HYBRIT”—hailed the achievement as a technological breakthrough that “is a decisive step on the road to fossil-free steel.”

“Production has been continuous and of good quality,” the companies announced on June 21. “Around 100 tonnes have been made so far.”

As HYBRIT explains it, the ore-based steelmaking value chain starts at the iron ore mine, where the ore is processed in the form of pellets, or “fines.” At a steelmaking site, the iron ore is conventionally converted to metallic iron by reduction of the iron ore pellets with coke in a blast furnace.…